Martin Engineering Optimizes Customer Site Up-time and Safety with Predictive Maintenance and Remote Monitoring Applications

Industry

Manufacturing

Infrastructure

AWS

Summary

- Martin Engineering develops data applications to help its customers monitor industrial bulk material handling equipment in disparate geographies such as mines and ports, facing challenges due to power and cost constraints

- The company focuses on designing low-cost solutions that are highly reliable and scalable, operating behind the scenes to help end users respond promptly to detected issues

- The R&D division aims to balance condition monitoring intricacies with constrained financial resources and extensive cabling expenses

Introduction

Martin Engineering is a global leader in bulk materials handling, specializing in the design and manufacture of innovative conveyor belt components and flow aids to help make operations cleaner, safer, and more productive. The company employs over 900 staff located across 17 global offices with manufacturing footprints in North America, Brazil, Turkey, Germany, India, China, Australia, and South Africa.

Martin Engineering runs product divisions focusing on mining and quarrying, cement and concrete production, steel making, pulp and paper production, power generation, and loading and unloading for bulk transport. Beyond manufacturing high-quality components, the company also provides world-class training as well as on-site installation and comprehensive maintenance services to ensure optimal performance throughout the component lifecycles. The company uses Dash Enterprise to effectively visualize and action remote equipment monitoring and maintenance data.

“What we really want to do is to delight our customers with data-driven insights. One of the things we measure is how fast they wear out their equipment — looking at ways we can improve asset utilization and performance by helping them to integrate these insights into the way they work with our products."

Mark Slack, Global Product Manager - Transformational Growth, Martin Engineering

Challenge

Monitoring equipment across vast, remote landscapes — particularly in expansive mines where power, cost, and connectivity considerations are paramount — poses a unique set of challenges.

The targeted equipment may not be high in cost individually, unlike massive mine trucks, but plays a crucial role for Martin Engineering's customers in tracking operational efficiency and performance, health, and safety. The company’s remote and sensor monitoring services help its customers reduce the risk of manual equipment maintenance at high-risk sites with confined and high-altitude spaces. Additionally, the company aims to maximize uptime and scheduled downtime for its customers.

Martin Engineering designs low-cost solutions for its customers that are also highly reliable and scalable. The company provides well-conceived and designed systems to its customers that operate almost unnoticed by end users yet respond in a timely manner when issues arise.

The company’s R&D division — working in conjunction with the transformational growth team — strives to balance minute condition monitoring with the constraints of limited financial resources and extensive cabling expenses.

Solution

The Martin Engineering R&D team explored several open source solutions, including Javascript-based data visualization frameworks, to build analytical web apps and dashboards for use by both internal stakeholders and other business units across the company.

After choosing Dash for Python data apps, the shift to Dash Enterprise was a logical next step. The change was driven by the practical need for easier app deployment along with the capability to more rapidly and easily create professional applications — particularly for external customer sharing — using the Dash Enterprise Design Kit theme editor.

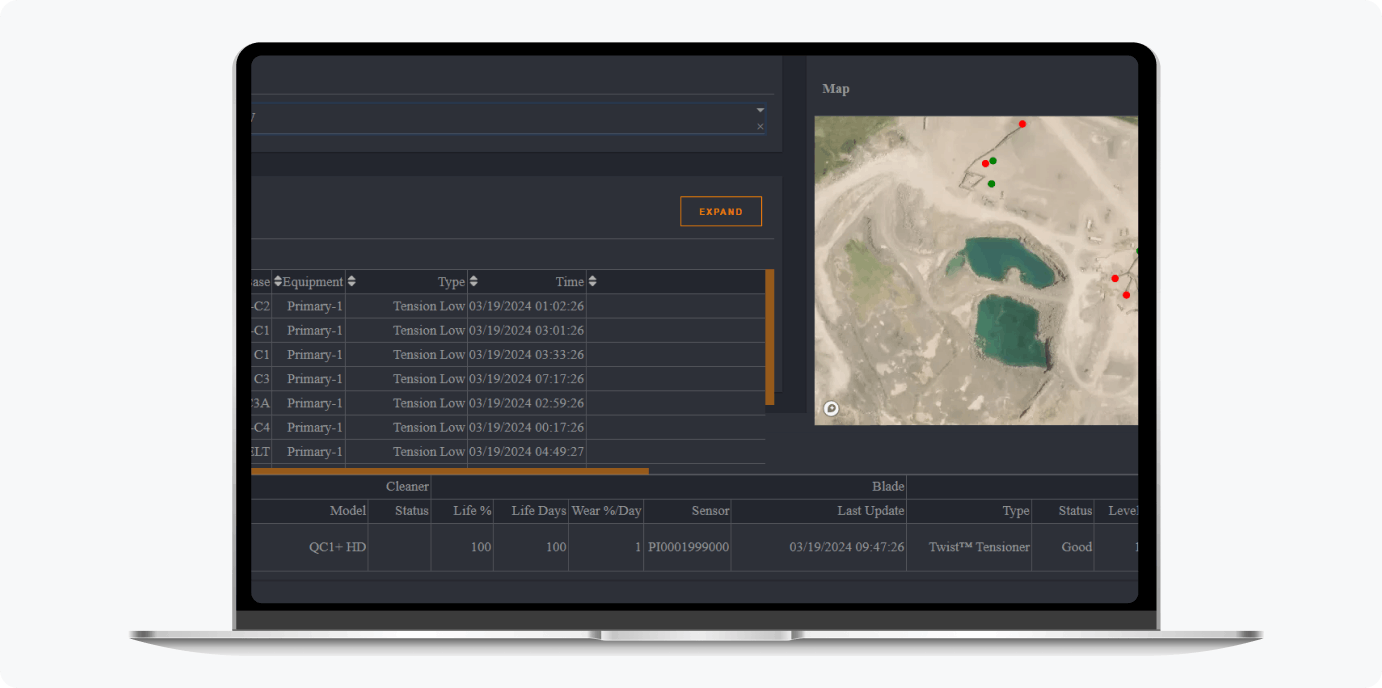

A look at Martin Engineering's on-site sensor information dashboard.

The team developed an application for aggregating data from on-site sensors, distilling, organizing, and presenting it through a contextualized dashboard. This information serves as a catalyst for Martin Engineering customers globally to address alerts, such as blade life reaching a critical low, displayed prominently for immediate attention. The integrated approach allows users to view alerts from multiple pieces of equipment side by side, facilitating coordinated actions. The application handles maintenance priorities and resource allocation efficiently.

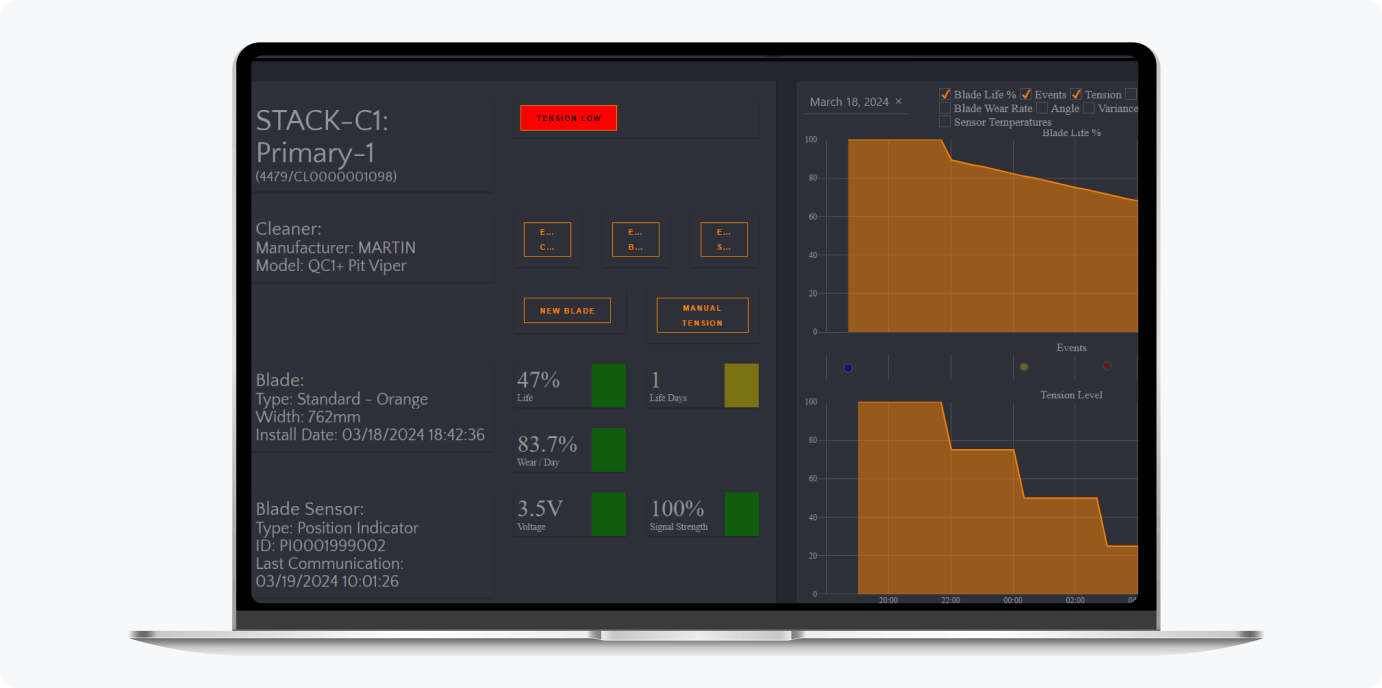

Drill-down for detailed view of on-site sensor information.

The data app architecture involves on-site sensors communicating with a gateway, utilizing third-party LoRaWAN gateways and servers for data transmission to a central location. Data is then processed through an AWS IoT core, leveraging Timestream, Dynamo, and RDS databases. The user platform also includes a native mobile app for on-site data input, integrating with sensor data in Dash Enterprise. The historical data from Timestream forms the foundation for app pages, providing a holistic solution for predictive maintenance and optimized resource deployment.

Results

By providing remote monitoring and maintenance data applications, Martin Engineering helps its customers operate in high-risk environments with efficiency, safety, and at optimal levels of performance.

- Risk reduction: The remote monitoring application helped remove individuals from hazardous environments, providing customers with the ability to eliminate exposure to these risks.

- Hazard elimination: The company achieved a 94% potential elimination of exposure to hazards over a 4-month period at a customer site, leveraging information from Plotly dashboards.

- Uptime optimization: For customers handling 100 million+ tons of raw materials annually, Martin Engineering's solutions delivered tangible uptime benefits with efficient use of production hours.

About Martin Engineering

Founded in 1944, Martin Engineering is the world leader in making bulk materials handling cleaner, safer, and more productive. The company specializes in manufacturing conveyor accessories and flow aids to help processes run efficiently and safely. Headquartered in Neponset, IL, Martin Engineering has global reach with operations in Australia, Brazil, China, Colombia, Indonesia, France, Germany, the United Kingdom, Italy, Spain, Indonesia, Mexico, Peru, South Africa, Turkey, and India.