NovaLabs Facilitates Access to Leading CFD Methodology for Stirred Reactor Scaling Using Plotly Dash

Industry

Healthcare & Life Sciences

Infrastructure

AWS

Summary

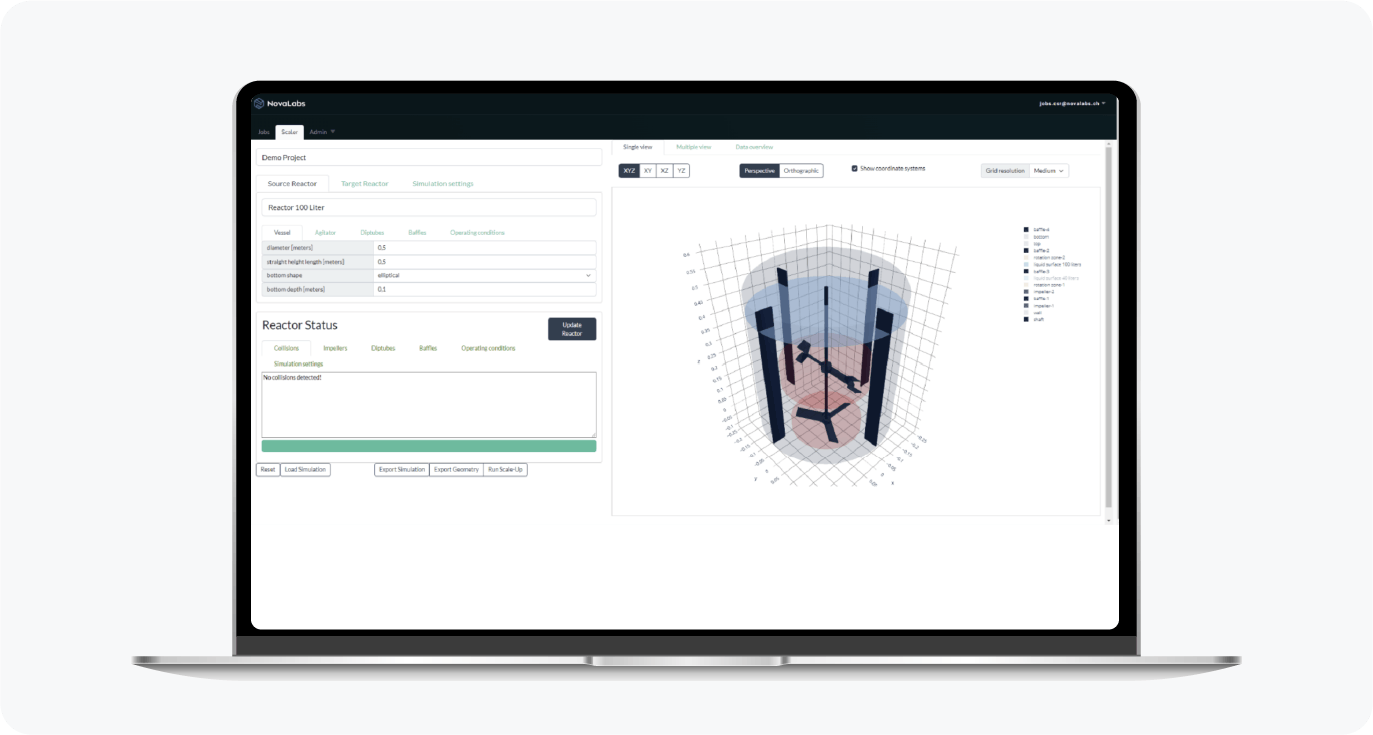

- NovaLabs developed a commercial SaaS offering (CliqScale.R) using Dash as the application framework, running on an AWS instance to explore 3D visualizations of reactor simulation models with user-defined settings.

- The application reduces lead time to access end-to-end CFD methodology for scaling stirred reactors from up to one year to a few minutes.

- Pharmaceutical companies can potentially save 7-digit figures by avoiding repetitive trials at scale, through the interpretation-ready results of the CFD methodology.

Introduction

CFD (Computational Fluid Dynamics) is a method to simulate the dynamics of liquids and gasses with a computer.

In the pharmaceutical industry, CFD is used for simulating mixing conditions in reactors where the active ingredients (API) of a medicine are manufactured. A common use case is the scale-up of a crystallization, which needs to be transferred to a different reactor with different scale.

CFD is used for simulating mixing conditions in reactors where the active ingredients of a medicine are manufactured.

The change in scale and equipment imposes a significant risk of failure due to the inherent changes of physics and mixing conditions. To reduce the risk, a CFD pre-screening is the method of choice.

Before starting with CFD for supporting such scale-ups, there are typically several tedious processes, including hiring an expert and the careful selection of hardware and software, easily resulting in an initial investment, typically between $70k and $100k, and a lead time of up to half a year. After running the first simulations, the development of a suitable methodology begins, taking months, resulting in a “method introduction and establishing time” in total of up to one year.

With CliqScale.R, NovaLabs changed this radically – using Plotly Dash.

Challenge

CFD as a part of a pharmaceutical company's tool stack is akin to having a ready-to-use laboratory (hardware) with all the base materials for synthesizing a new substance (software) but no recipe to address your patients’ needs (stakeholders). The "recipe" in this analogy is referred to as methodology, and when followed, delivers easily consumable, interpretation-ready analytics results.

Setting up this end-to-end toolchain requires knowledge in computational science, engineering, and coding as well as domain knowledge to choose the right methodology. It must be easily accessible and easily usable to be understood by non-expert users.

To satisfy the requirements above, CFD requires an industry-approved methodology provided as an instantly accessible and usable end-to-end solution. NovaLabs developed CliqScale.R to address this need.

Solution

To provide an end-to-end solution of the CFD methodology there are several steps needed:

- Building geometries that represent the reactors: This process can be done with a CAD kernel. NovaLabs used open cascade bindings for Python to build parametrized models of the reactors. The team developed their own modules and interfaced them with Dash through module import. When building CAD models, visual feedback is important so the team used the Plotly 3-D viewer to visually represent the geometries while building them online.

- Setting up reactor simulation conditions: The required parameters, including the number of simulations needed for informed decision making, are provided through the Dash GUI and are stored in a JSON file, which defines the complete simulation setup.

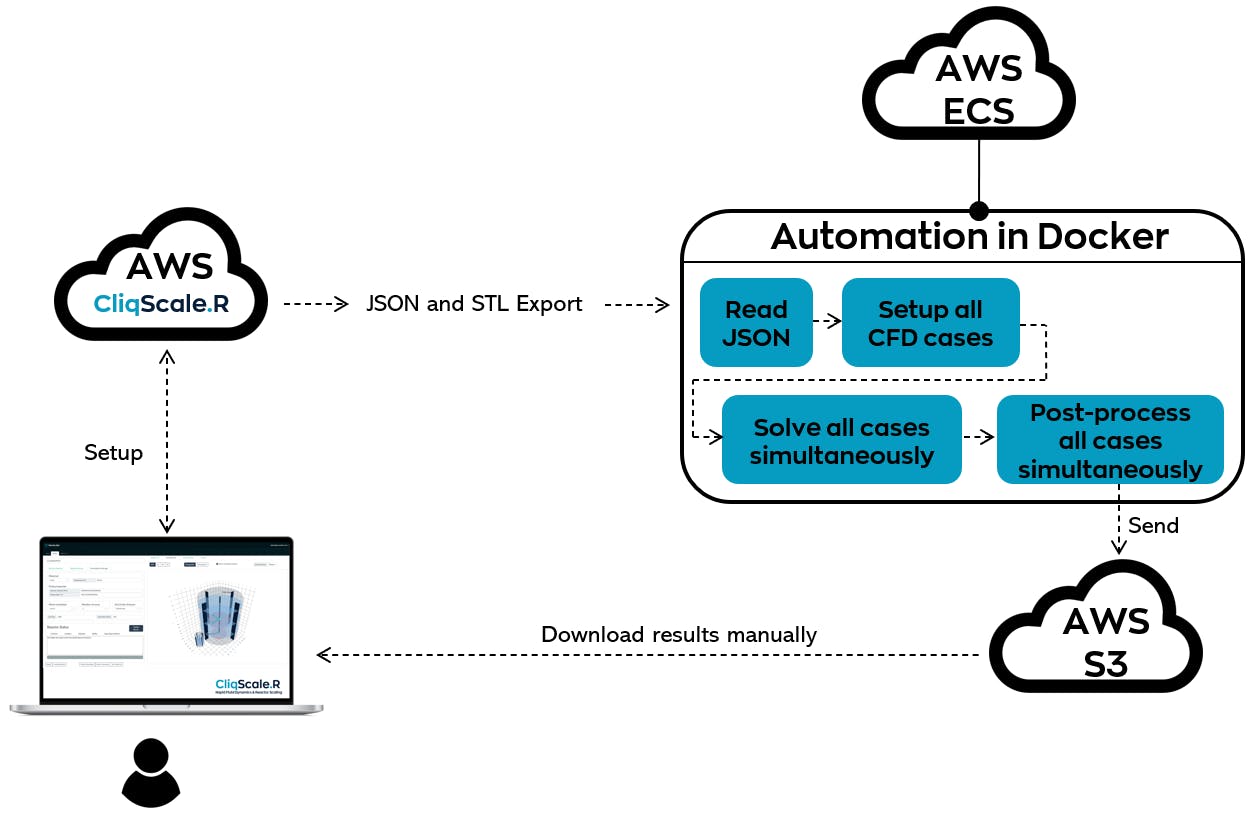

- Building all CFD cases from the JSON file: This step is performed in a fully automated way including meshing, setting the boundary conditions, and running all simulations simultaneously. This was implemented using internally developed Python modules and shell scripting.

- Automated post-processing of the CFD solutions: The post-processing was done by the team using Python and shell scripting to obtain interpretation-ready results that can be included in reports straightaway.

The Dash app where all settings are defined by the user runs on an AWS instance and can be accessed by different users simultaneously making sure the online-generated data is associated correctly through tokenization and a token-associated data folder. The automation part is decoupled from the app and runs as a containerized application on AWS ECS. The results are stored in a S3 bucket and can be accessed through a download link.

The data application workflow scheme.

Results

With the development of CliqScale.R, the NovaLabs team enables pharmaceutical companies to achieve the following results:

- The lead time for a typical pharma company to access a ready-to-use, end-to-end CFD methodology for scaling stirred reactors is reduced from one year to minutes due to the subscription-based SaaS approach.

- The methodology helps reduce the risk of failure for scale-up significantly, due to a CFD pre-screening of differences between the two reactors. The result is a significant reduction of repetitive trials at scale which can save costs from several hundred thousands up to a million, particularly at commercial scale. [1] [2]

- The used methodology provides interpretation-ready and report-ready results like comparative statistical distribution plots between the source and target reactors including a proposal for setting the stirring speed for the target reactor that matches the conditions in the source reactor.

“With Dash, we built our web application without the need of a full-stack developer or learning a new language internally. It is the ideal framework for rapid prototyping, but also to build highly professional and comprehensive apps. By interfacing Dash with a CAD kernel, we went beyond the typical application, which shows the openness and flexibility of Dash. We are very happy with the result and would appreciate seeing more apps like CliqScale.R!”

Antonio Liggieri, Founder and CEO, NovaLabs

About NovaLabs

NovaLabs provides services for computational engineering, machine learning, and scientific software development. Its mission is to assist companies in making better decisions through its computational expertise and to save cost, time, and resources for a more sustainable future, with its flagship product, CliqScale.R.

References

1. Frank Delvigne, Ralf Takors, Rob Mudde, Walter van Gulik and Henk Noorman, TERRA Research Center, Microbial Processes and Interactions (MiPI), University of Liege, Liege, Belgium. Institute of Biochemical Engineering, University of Stuttgart, Stuttgart, Germany 2017

2. V. Atiemo-Obeng, S. Kresta, E. Paul. Handbook of Industrial Mixing: Science and Practice (Wiley, Hoboken, NJ, 2004)